Wine Making Process

Wine bottling, fermentation, grape pressing, traditional method...

What does it all mean? The sparkling winemaking process can sound complex, and the world of wine can feel a little intimidating.

But that’s not the CHANDON way. Everyone’s welcome at our table—and we believe in making wine approachable, not exclusive. So let us break it down and show you how the magic really happens.

Exploring The Traditional Method

Crafting exceptional sparkling wine takes more than just skill—it requires deep expertise, technical precision, and a winemaker’s vision to anticipate how the wine will evolve years after harvest.

At CHANDON, we use the Traditional Method—also known as Méthode Traditionnelle—the time-honored technique behind every bottle of our sparkling wine. Here’s how it all comes together.

PHASE 1

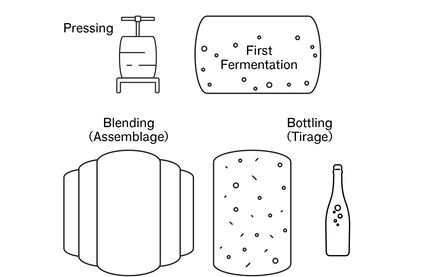

In sparkling winemaking, it’s crucial to press the juice from the grape skins as quickly and gently as possible to avoid extracting color, tannins, or phenols. Grapes are harvested under the stars to keep them cool and preserve freshness. Upon arrival at the winery, they’re swiftly transferred from the truck to the press. This press slowly inflates, gently squeezing the juice from the skins with minimal pressure. The clear juice is then sent directly to tanks for fermentation, while the skins and seeds are separated and removed for composting.

After the initial fermentation, the wine is filtered to remove any remaining solids, and the blending process begins. Wines from different grape varieties and vineyards—often kept separate—are carefully tasted and combined with reserve wines from previous years to create the final cuvée. A single cuvée can include up to 80 different lots, making blending the true art of sparkling winemaking.

This process relies on the winemaker’s skill to balance old and new vintages, merge characteristics from various vineyards, and harmonize different grape varieties. The winemaker must also anticipate how the blend will evolve during aging and how it will perform after the secondary fermentation, once the bubbles form.

Once assembled, the cuvée undergoes cold stabilization to prevent the formation of tartaric crystals in the bottle. These crystals can cause the wine to gush upon opening if not removed, so cold stabilization is a crucial step to ensure a clean, stable sparkling wine.

With the cuvée ready, the next step is tirage—literally “drawing from” the tank into the bottle. The wine is transferred to a tirage tank where a precise amount of sugar and active yeast are added. Since the natural grape sugars were fully fermented during the initial fermentation, this added sugar is essential to fuel the secondary fermentation that creates the bubbles.

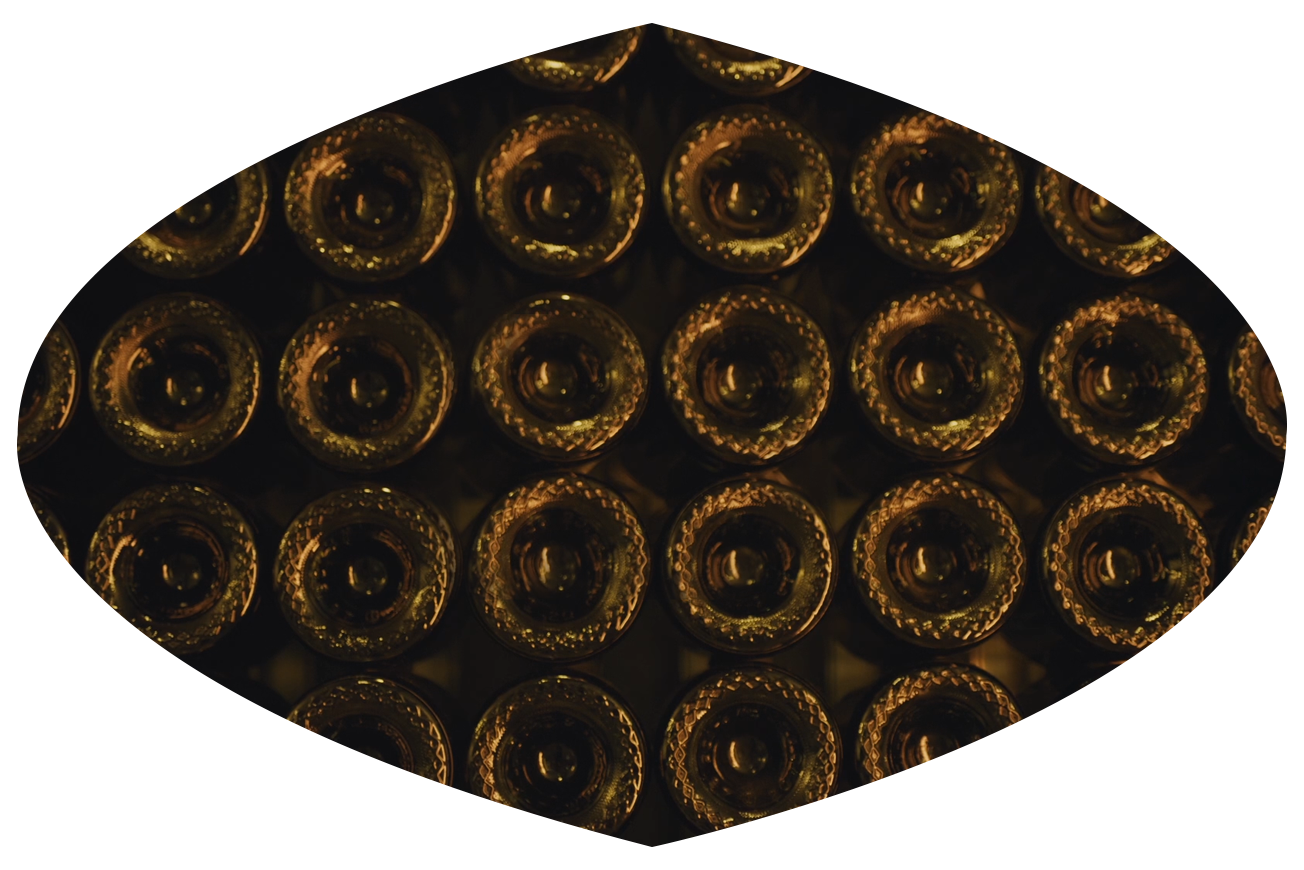

As bottles are filled, a small plastic plug called a bidule is inserted to form a tight seal. A crown cap is placed over the bidule, and the bottles are laid on their sides to begin the second fermentation.

PHASE 2

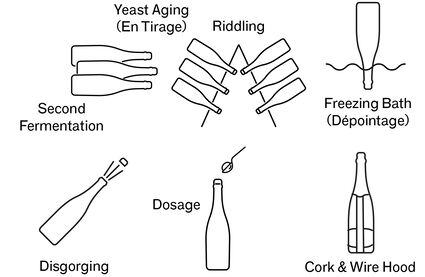

The young sparkling wine is left to age undisturbed for at least a year and a half. Early in this aging process, the spent yeast cells begin to break down—a transformation that brings about significant changes in the wine.

As time passes, the wine evolves, developing greater complexity and a distinctive bouquet. When the winemaker feels the wine has reached its optimal maturity, it’s ready to move on to the next stage of production.

After riddling, the bottles—now neck-down with all sediment settled into the bidule and crown cap—are carefully removed from the racks and placed into a brine bath chilled to around –26°C (–15°F). Within about 15 minutes, the neck of each bottle freezes to a depth of roughly an inch, trapping the sediment in a solid ice plug.

The trapped sediment, known as lees, is then removed through disgorging. When the crown cap is loosened, the internal pressure of the carbon dioxide forces the bidule and frozen sediment plug to eject, leaving the wine clear and sediment-free.

Finally, the sparkling wine is topped off with a precise amount of dosage—a blend of cane sugar and wine—that balances the wine’s flavor and sweetness, perfecting its taste before the final corking.